Downcycling PLASTICS from rivers // Plastik aus Flüssen downcyclen

Downcycling – better low value than no value at all

A global study of 1,350 rivers revealed a striking fact:Just ten rivers are responsible for the majority of plastic waste entering the oceans.

Among the main contributors are the Nile, the Niger, and eight major rivers in Asia.

Even more sobering:less than 5% of all plastic produced worldwide is actually recycled.So the obvious question is:

👉 Where does the remaining 95% go?

(Short answer: into landfills, rivers, oceans… and eventually into us.)

Catch it before it reaches the sea

# Instead of trying to fish plastic out of the open ocean, the smarter move is to stop it at the source.

Imagine this:

# At the delta of major rivers, endlessly circulating collection nets are installed along both riverbanks.These floating net loops gently guide plastic debris with the current, skimming it off before it reaches the sea.

- The nets extend slightly toward the river center

- They are spaced to allow safe boat passage

- No dams, no blocking, no drama

# From river to recycling — automatically.

# From trash to raw material

One promising example is the technology developed by RECENSO (www.recenso.eu), which enables mixed plastic waste to be converted back into:

- liquid raw materials

- universally usable feedstock for industry

Similarly, KIT pyrolysis reactors heat plastic waste to recover valuable base materials.

Similarly, KIT pyrolysis reactors heat plastic waste to recover valuable base materials.Is it perfect recycling?

No. Is it far better than dumping plastic into the ocean forever?Absolutely.

A small but important detail: driftwood

Upstream, two additional coarse collection nets are installed to catch heavy driftwood and debris.This protects the finer plastic nets from tearing — because even saving the planet needs good engineering.

And about microplastics…

# Of course, not all plastic floats nicely into nets.

# Microplastics remind us that:

- unnecessary car trips matter

- plastic clothing sheds fibers

- excessive packaging adds up

In short

- Stop plastic before it reaches the ocean

- Accept downcycling where recycling fails

- Turn waste into raw material

- Combine technology with common sense

© Michael Thalhammer, Vienna, 8. December 2019 / KI-Verbessert, Dec.2025

_________________

UPCYCLING for Cargo Ships

Each of the tens of millions of cargo ships that cross our oceans is downcycled in third world countries after its seaworthy service life.

These constructively valuable superstructures could instead be given a second, useful life:

On moorings or pulled ashore with the keel upwards, they would - with an appropriately extended operating licence and converted into multi-purpose premises - continue to provide valuable services for many years to come. Whether as a school, opera house, museum, department stores', gallery, hospital, restaurant or for communal living, such a ship's belly offers many possibilities. In new builds, such facilities cost scarce resources anyway, take up a lot of urban space and hardly have any more living space.

These approaches should also be considered by UNHCR and UNIDO for further implementation.

© Michael Thalhammer, Wien, Dezember 2019

============

Rough vacuum application in the interior of freezer and cold storage rooms

Suggestion for the manufacturing industry of refrigerators, refrigerated containers, refrigerated lorries, refrigerated wagons etc..

Designed as an airtight cooling housing, a low vacuum is generated by a vacuum pump when the door is closed in order to keep the stored food fresh for several times longer (Tupperware® effect).

When the door closing mechanism is actuated, the air sucked out can immediately flow back in again (pressure equalisation). The door handle recessed in an olive first opens the air inlet valve. Only after this immediate pressure equalisation can the door be opened without resistance.

Each time the door is closed, a sensor or switch causes the air to be pumped out again; however, the sensor can also be deactivated.

The condensation drain allows the liquid to drain away each time the cold room is opened (via a vacuum ball valve). When the door is closed or the air is evacuated again, the valve closes this drain again.

© Michael Thalhammer, in Baden near Vienna, 26 February 2013

==============

MUD WORK BOOTS - THAT DON'T GET STUCK IN THE MUD

Of course, there are already a large number of different rain boots on the market. From work to fashion, there are models for every need, but there is also a need for work in boggy deep mud, which is particularly energy-sapping.

To ensure normal walking in viscous wet mud, an open, integrated 2 mm air channel, which runs down the calf shaft in the boot and then through the heel sole to the instep arch, is all that is needed.

This means that the foot does not have to form a strenuous suction stamp with the boot, and you can walk almost unhindered as if on neutral ground.

It is irrelevant that this channel absorbs some of the mud with every step, as this amount is easily released again pneumatically.

© by Michael Thalhammer - Vienna, on 21.10.2019

==============

Here you will find useful and practical inventions by others:

==============

Similarly configured, floating river turbines could be placed in parallel as large carpets and supply large amounts of electricity. Each of these paddlewheel rollers in combination would already provide valuable, cheaply generated operating power in the kilowatt range, 24 hours a day. See also: Electricity buoy from AquaLibre,

web: www.powerfluxx.com , web: www.aqualibre.at

© Michael Thalhammer, Vienna, 8. December 2019.

=================

Inflatable wings for cargo ships too

90 % of all long-distance freight is transported by "dirty" sea routes.

This should and must change in the future. Now it can be realised easily and cheaply! With the simple and revolutionary invention of two Swiss inventors, even 1000 m² sail areas can be realised. Large ships can even be equipped with several thousand square metres of wind power.

See the 8 min. VIDEO:

https://www.yacht.de/yacht_tv/test_technik/ist-der-aufblas-fluegel-die-revolution-des-segelns/a118866.html

also: www.inflatedwingsails.com

IWS consist of a double skin as a symmetrical flow profile. Fans in the leading edge stabilize the sail shape for all wind conditions and a free-standing, retractable mast is at the aerodynamic center of the wing.

The advantages of IWS: The sail flies vertically. The NACA profile was created to develop high driving force for a low righting moment. The symmetrical airfoil is balanced and in the best position to maximize driving force. The aerodynamic center remains stable in all wind conditions. This type of sail can be operated in system automation.

IWS reduces effort on the boat: Shape control via internal pressure, no slats, no local stress. The wing flies vertically and does not create local tensions in the membrane, lightweight canvas.

Little heel angle against the wind. Perfect for gigantic sails such as superyachts, oil tankers etc. Freestanding, retractable and lightweight mast hidden in the wing.

IWS behaves like a muscle, STABILIZED BY HIGH PRESSURE. No compressive forces in the rigging, allowing the use of a retractable mast. Deflating the IWS is done by deflating the wing and retracting the mast. The lightweight boom, is integrated into the wing and accommodates the part of the sail that has been dropped and deflated. These approaches should also be considered by UNIDO for further implementation.

=========

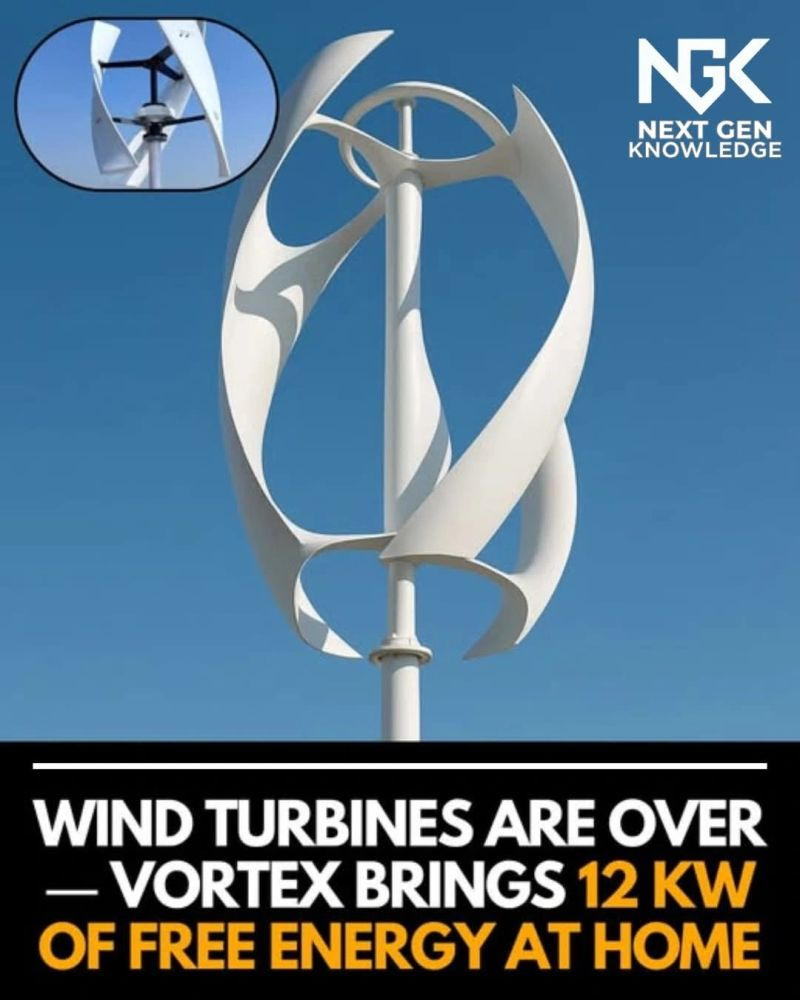

V O R T E X - P L A D E L E S S may make conventional wind turbines redundant

HOW IT WORKS? compared to a conventional turbine of the same size:

# Low maintenance

# gearless and oil-free

# No braking necessary

# always orientated

# SIMPLE MANUFACTURING PROCESS

# lower wind range

# lower wind range# Less space required

# Longer service life

STRUCTURE & FUNCTION

Vortex devices are quite simple in concept and are easy to manufacture, install and operate.

They consist of a fixed base and a cylindrical mast that swings freely perpendicular to the wind direction and is connected by a carbon rod.

The inner parts never collide with each other, but interact to generate electricity.

When the wind flows around a structure, pressure vortices are created.

The frequency of the vortices depends on the wind speed, and if the structure has a similar natural resonant frequency, it begins to vibrate and utilise its energy.

This phenomenon of aeroelastic resonance is called vortex shedding and occurs regularly in nature.

ENERGY CONVERTER

Similar to a conventional alternator, our device creates an interaction between coils and magnetic fields that generates electricity through electromagnetic induction without the need for rotation on a shaft or gearing.

The magnets also act as a ‘tuning system’ by changing the apparent elasticity constant of the mast, thus extending the wind speed range in which oscillations occur.

POTENTIAL APPLICATIONS

As our devices require little maintenance and (like solar panels) are harmless to wildlife, they open up new horizons for wind energy in urban areas and nature reserves.

However, they can also utilise the installation zones of conventional wind power, allowing this technology to exploit its own properties for large-scale production in classic wind farms or huge offshore installations.

Sorce: www.vortexpladeless.com